You are here: Start > Yacht-technics > Products and Services > Electric propulsion systems > POD drives

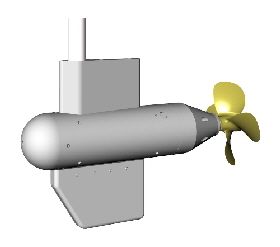

Electric POD - drive

If your ship has had neither a shaft drive nor a sail drive, but was only operated with an outboard motor, the electric POD drive is the optimal and easiest to implement solution for efficient motorization.

The assembly of a POD drive is very easy compared to the subsequent installation of a shaft drive system or a sail drive.

Neither major breakthroughs on the hull nor engine foundations are required. Also no exact adjustment of the engine is required. It only has to be ensured that the thrust forces introduced by the engine are safely transmitted to the hull.

Otherwise, depending on the manufacturer and model, only 2 - 6 holes of 8, 10 or 12mm are to be provided for the fastening screws of the motor on the fuselage and a slightly larger hole for the electrical cable bushing.More assembly effort is not required.

The necessary electronic motor control unit may be mounted separately from this in a dry place on board, so it doesn’t necessarily have to be installed directly nearby the engine. This means, that the POD drive is also ideal when there is limited space in the bilge.

Of course, there is the option of recuperation, i.e. using the engine as a generator while sailing. Our POD drives EFM for example have a high performance recuperation up to 50%.

EFM-48-7.5 with fin

The standard scope of delivery of the EFM POD drives includes all components required for operation, only the batteries and the charger, possibly a special version of the propeller, e.g. folding or rotating blade propeller, are additionally required.

Those who value optimal maneuverability should choose the steerable POD drive, which has been tried and tested in large shipping for a long time.

This means that the tightest turning circles are possible both forwards and backwards.If the steering system allows this, i.e. depending on the selected rudder quadrant, the POD can also act as a side thruster with a steering angle of 90°.This means that even the narrowest berth gaps are no longer a problem.

The installation effort is only slightly higher compared to the fixed flange motor. Instead of the mounting holes, a hole for a Hennegatt pipe is provided in the hull. This must then be firmly connected to the hull. The motor rudder shaft is inserted through the Hennegatt pipe, on which the rudder quadrant or, in the case of smaller drives, the tiller is then mounted in the boat. The conventional rudder system can then be omitted

10kW steerable POD-drive

Benefits of the POD drive:

- low assembly effort

- lowest space consumption inside the boat

- optimal flow towards the rudder similar to shaft drive or sail drive

- maintenace free thanks to the newest BLDC motor technology

- lowest drag while sailing, even with a fixed pitch propeller

- very high efficiency

- low weight

- standard shaft 25mm with cone 1:10 and M16x1,5 propeller nut

- optimum price- / performance ratio

- depending on the model, recuperation is optionally possible

- steerable POD-drive optionally possible

|

< c> Bode Industrie und Marineelektronik 2002 ...2023 |

|

|

Redaktionsschluß 19.04.2023 |

|